DATE 2016

LOCATION LONDON

STATUS COMPLETED

CLIENT FOOD INK

TEAM

Mamou-Mani (Arthur Mamou-Mani, Rishabh Khurana, Ping-Hsiang Chen, Lola Chaine)

Food Ink (Antony Dobrzensky, Marcio Barradas, Mateu Blanch, Joel Castanye, Frits Hoff, Floris Hoff, Jerome Vadon)

Thanks

James Solly, Oliver Fueckert, Florian Horsch, Aaron Porterfield, Andrei Jipa

Our Smoke Stool has been listed as a 3DPC Finalist 2017 of the Pioneers Challenge 17.

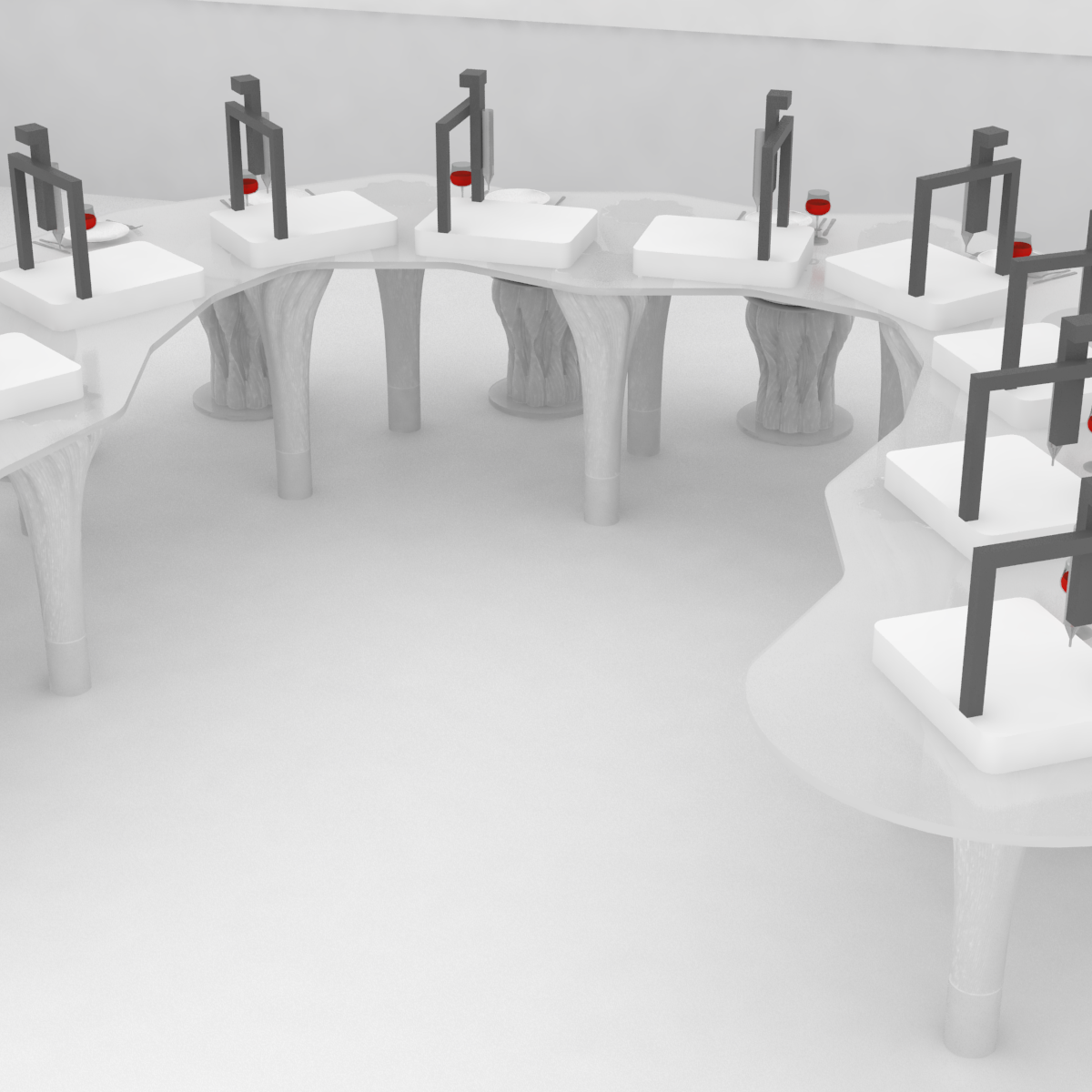

Bringing together architects, artists, chefs, designers and engineers, pop-up restaurant Food Ink. has laid claim to the title of “world’s first 3D-printing restaurant.” The restaurant utilizes 3D printers produced by Dutch company byFlow to create dishes out of hummus, chocolate mousse, smashed peas, goat cheese or pizza dough – essentially anything that can take the form of a paste.

The paste can then be fed through the extruder to create culinary sculptures. Food Ink.’s mission is to explore the intersection between dining and technology-enhanced user experience. According to their stated philosophy, the team is “putting [to] work most innovative technologies, like 3D-printing and augmented reality, in order to elaborate the most exquisite interactive edible experience.”

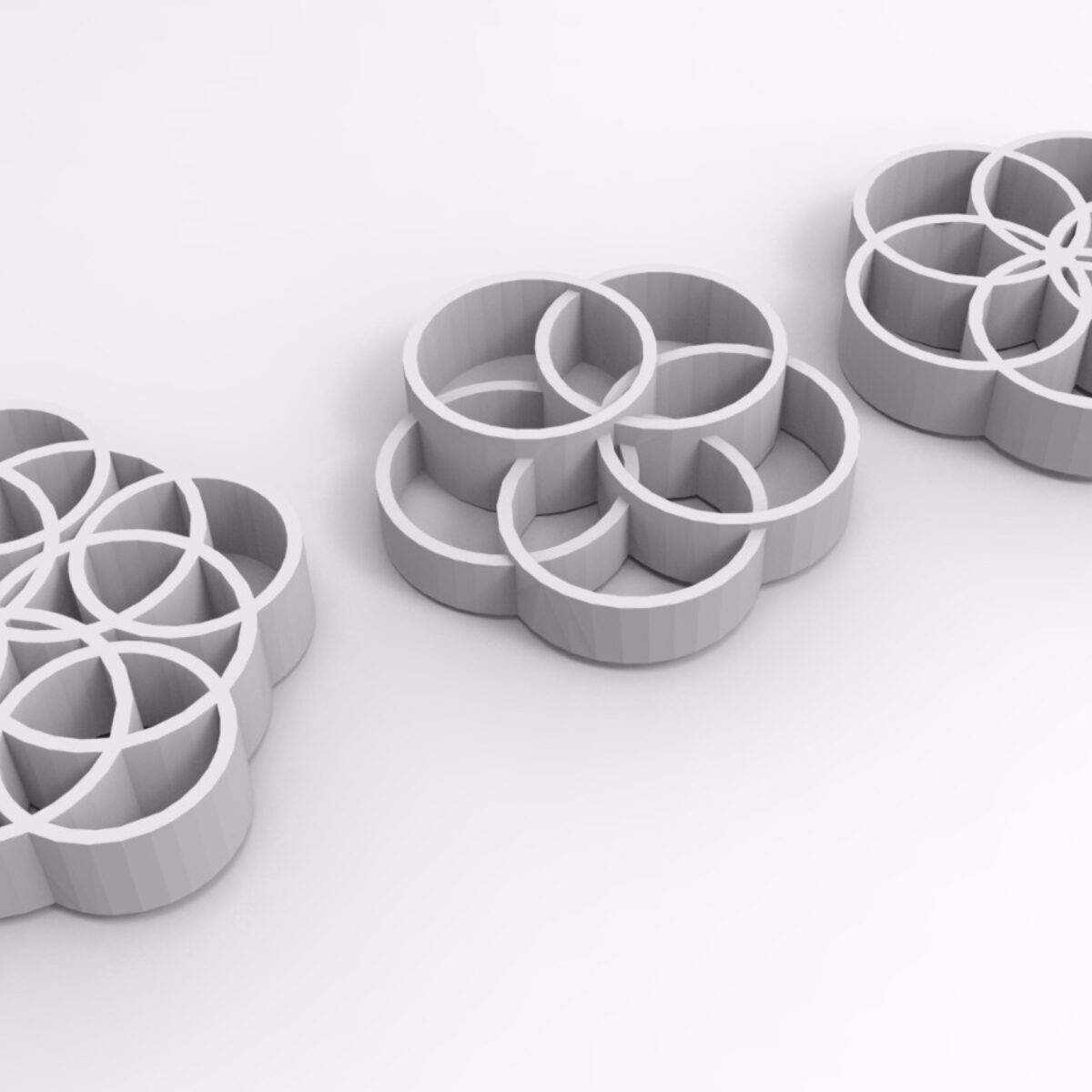

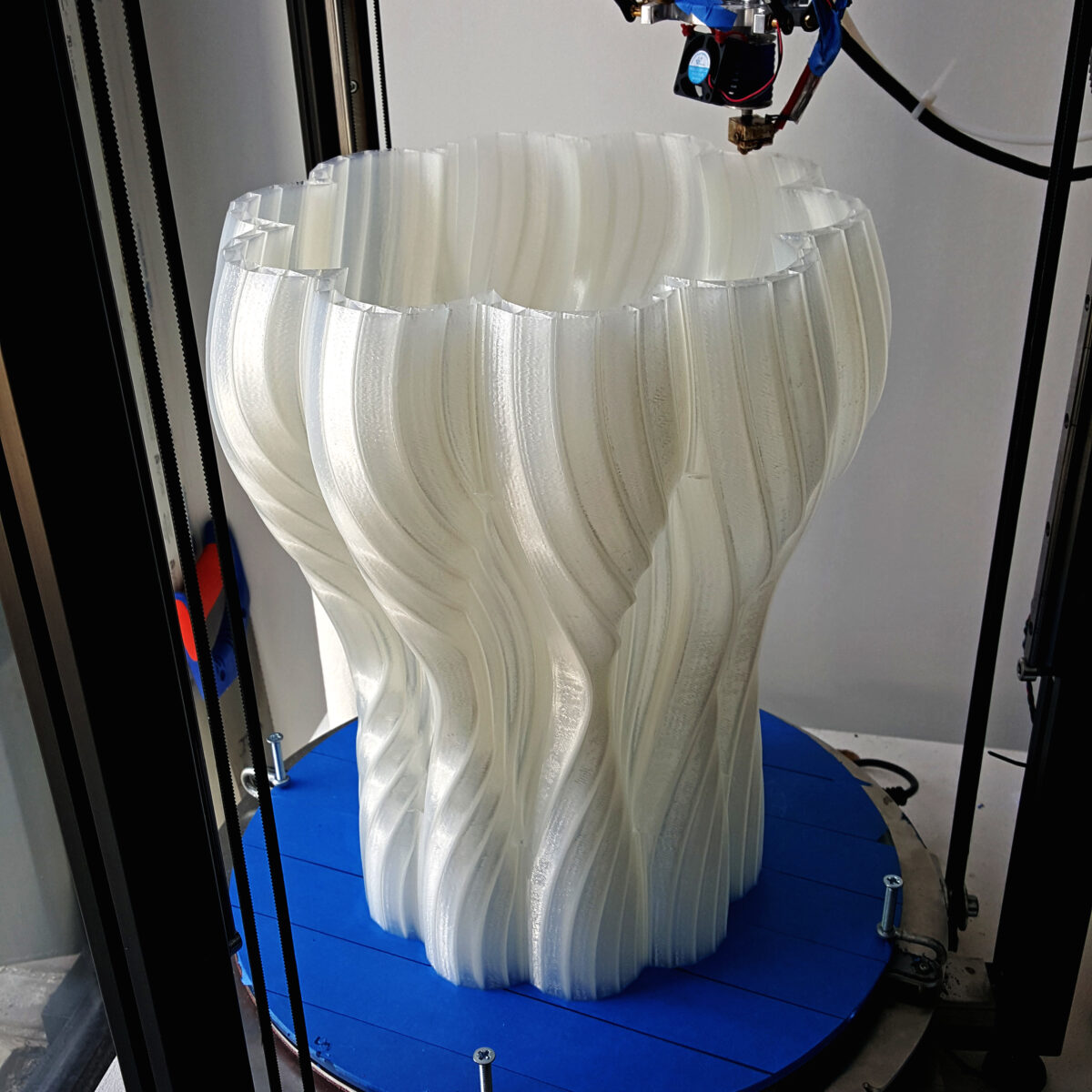

In addition to translating geometries into 3D printing pathways, Silkworm allows us to manipulate the internal geometries and structures of his designs to fit desired time, speed, and build constraints. To ensure the stability and strength of the 3D printed stools, Mamou-Mani incorporated a truss structure into its walls, ultimately allowing for a sturdy, hollow, and materially efficient structure that could withstand being sat on.

In designing the whole collection, which consists of a number of different designs, Mamou-Mani and his team generated a matrix of potential chair designs which took into account the desired speed of the print, the angle behind the print, and a number of other factors. The result was a range of design families that fell into these constraints. To account for the height limitations of the 3D printer, some of the pieces were designed with male/female connections for possible extensions.